components

Hardware Components

Source Control

TODO: Upload firmware + software

Project Description

Ethernet Controlled Mini Tabletop Reflow Ovens

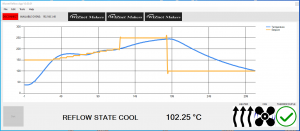

Low power, very small reflow oven that is quick to put together and several can be controlled over Ethernet by one PC app. Due to time constraints it currently controlled by a PC winforms app but will hopefully be moved to Web soon.I make lots of prototypes but send off the designs to get made at the PCBA house. I needed a very small, low energy consuming device. I also wanted to be able to have a histogram of the reflow process to identify an reflow profiles at a later date. Make no mistake the hardware can support any toaster oven or larger depending on the SSR relay rating.Various profiles can be programmed in for each specific oven. Could not test this because I only have one sample but will try source more.Upon powerup the W5100s-EVB-Pico get it's IP Address via the network router. It then waits for broadcast from the WiznetReflow app. On the network UDP is used. The wiznet reflow hardware then registers with the app a unique ID (this is to uniquely identify the hardware if several units are online). The current state, thermocouple temperature etc are send periodically between the PC app and the wiznet hardware. The reflow process can be started / stopped manually by a button on the wiznet hardware OR via the PC app.Below is an image of a recorded reflow process.

This is an image of the heater elements that were used.

The project uses two. Very cheap, very reliable, very powerful

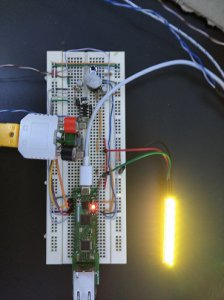

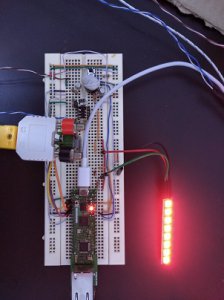

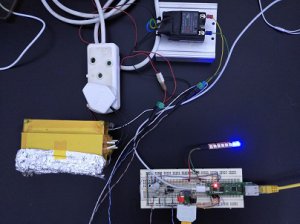

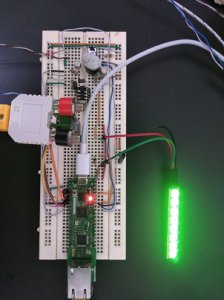

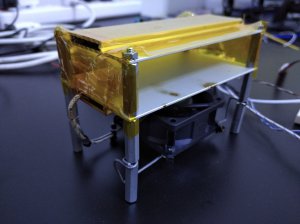

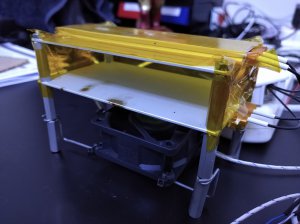

Here are some pictures of the setup. Unfortunately there was no time to get a PCB made. There are different lighting effects for the various phases of operation on the physical hardware displayed on a Neopixel type 8x Ws2812 led strip.

Here are some pictures of the setup. Unfortunately there was no time to get a PCB made. There are different lighting effects for the various phases of operation on the physical hardware displayed on a Neopixel type 8x Ws2812 led strip.- Power up /loading: WHITE

- Reflow IDLE: GREEN

- Reflowing: Alternating RED/ORANGE

- Cooling: Knight Ride rolling BLUE

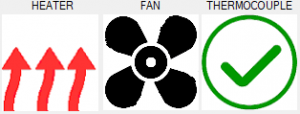

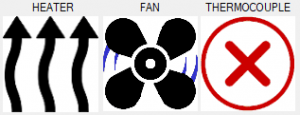

PC App has indicators based on the status of the reflow hardware via the W5100s-EVB-Pico over ethernet. Heater, Fan and thermocouple pictures display and animate accordingly.

PC App has indicators based on the status of the reflow hardware via the W5100s-EVB-Pico over ethernet. Heater, Fan and thermocouple pictures display and animate accordingly.

Other Toaster ovens that can be used

If I have larger PCB's to reflow I just connected this oven's thermocouple & power to my reflow hardware. TRICK: Use aluminium foil and Kapton tape to hold the foil up to block off the bottom half of the oven so you DO NOT NEED TO MODIFY it. I only used the top 2x elements ! ! !

Finally Pics Of Mini Oven

documents

Unfortunately my W5100S-EVB-Pico has only arrived in the country yesterday (10 March 2022). Hopefully I can make up the time and complete my project as close to what I envisioned as possible. I may need .Net Core app vs Web

Dear Benjamin, final project can be submitted by April 30. Good luck in your implementation!

Thanks for letting me know. The shipment has been scanned at my local post office yesterday. “3/24/2022 8:35 AM Arrival at inward office of exchange CAPETOWN A”. Looking forward to seeing what the Wiznet module is capable of!

Is it possible to change the “Project Title” to “PC controlled Ethernet Mini Reflow Oven”? Not sure how the title ended up my email address 🙁

Finally the W5100S-EVB_Pico dev kit has arrived. I have collected it at the local post office (paid customs duties). This does not leave much development time now to meet the submission deadline, else will go onto youtube

The W5100S-EVB-Pico power up and Arduino 2.0 RC6 connectivity is working on a Win10 machine. I tested the board against an Example blink program & functions correctly. Took about 5 minutes to get it working.

NB: When first connecting to PC, Arduino will NOT find the board

– Select example project

– Add serial port to print ‘hello’

– Build it

– Copy the *.uf2 file onto RPI:

– May need to restart Arduino

– Upload from Arduino from now

Update: Project almost completed. The Arduino based project is now successfully reflowing PCB’s. Buttons, Neopixel display, buzzer, fan, ovens & SSR all operating correctly. Busy now integrating Ethernet into firmware & software

Update: Lots of admin still remaining like list of components etc but will post asap

How awesome is the W5100S-EVB-Pico?!! It was very quick to get a solid project up and running. Graphics took most of the time and implementing new libraries that supported the new RP2040 like the MAX6675 library. Thanks Wiznet

thanks for your submission. our committee started project evaluation. fingers crossed!

test

Hi benjaminemmerich,

I’m Ron from WIZnet HK. Could I post your article to our WIZnet HK instagram account?

BTW, do you have a instagram account that I could tag you?

Best Regards,

Ron